Materials technology

Tested to the limit

Which of these materials is best suited for discharge pipes, that are in service for decades on

end?

Test material samples in different highly concentrated solutions and find out which material is

the most robust. To do so, drag the samples into the different bowls.

Sulphuric acid (i.e. in batteries)

Sulphuric acid (i.e. in batteries)

Ethyl acetate (i.e. in nail varnish removers)

Ethyl acetate (i.e. in nail varnish removers)

Acetone (i.e. as a solvent for fats)

Acetone (i.e. as a solvent for fats)

| PA | PS | PE | PVC | |

|---|---|---|---|---|

| Sulphuric acid | ||||

| Ethyl acetate | ||||

| Acetone |

Only polyethylene does not react in any of the three solutions. This material is therefore suitable for discharge pipes and is used by Geberit for drainage systems as well as for a number of other products.

Probing the limits

Sanitary products have to work perfectly for decades. This is why Geberit attaches utmost importance to selecting the best possible product material. In its own laboratories, Geberit systematically goes to the limits – and beyond.

Today, plastics technologists and product developers can choose from thousands of different materials, many of which are subject to ongoing further development and optimisation. This also includes polyethylene – a key plastic in the thermoplastics class (the lead picture of this annual report shows black-coloured plastic granulate for Geberit fittings).

The wide world of polyethylene

Geberit uses polyethylene (PE for short) in different compositions to manufacture products such as cisterns, components of building drainage systems and drinking water pipes. The most suitable PE type is evaluated for each product in the company’s own materials laboratories.

High requirements

In sanitary technology, the service life of a material is one of the most important selection criteria. For example, plastic pipes for drinking water and discharge piping systems in buildings have to fulfil extremely demanding functional specifications according to ISO standards and yield a certified service life of 50 years. As it would not be realistic to test new materials for 50 years before they can be used in practice, the ageing process has to be accelerated during the testing phase.

Comprehensive testing

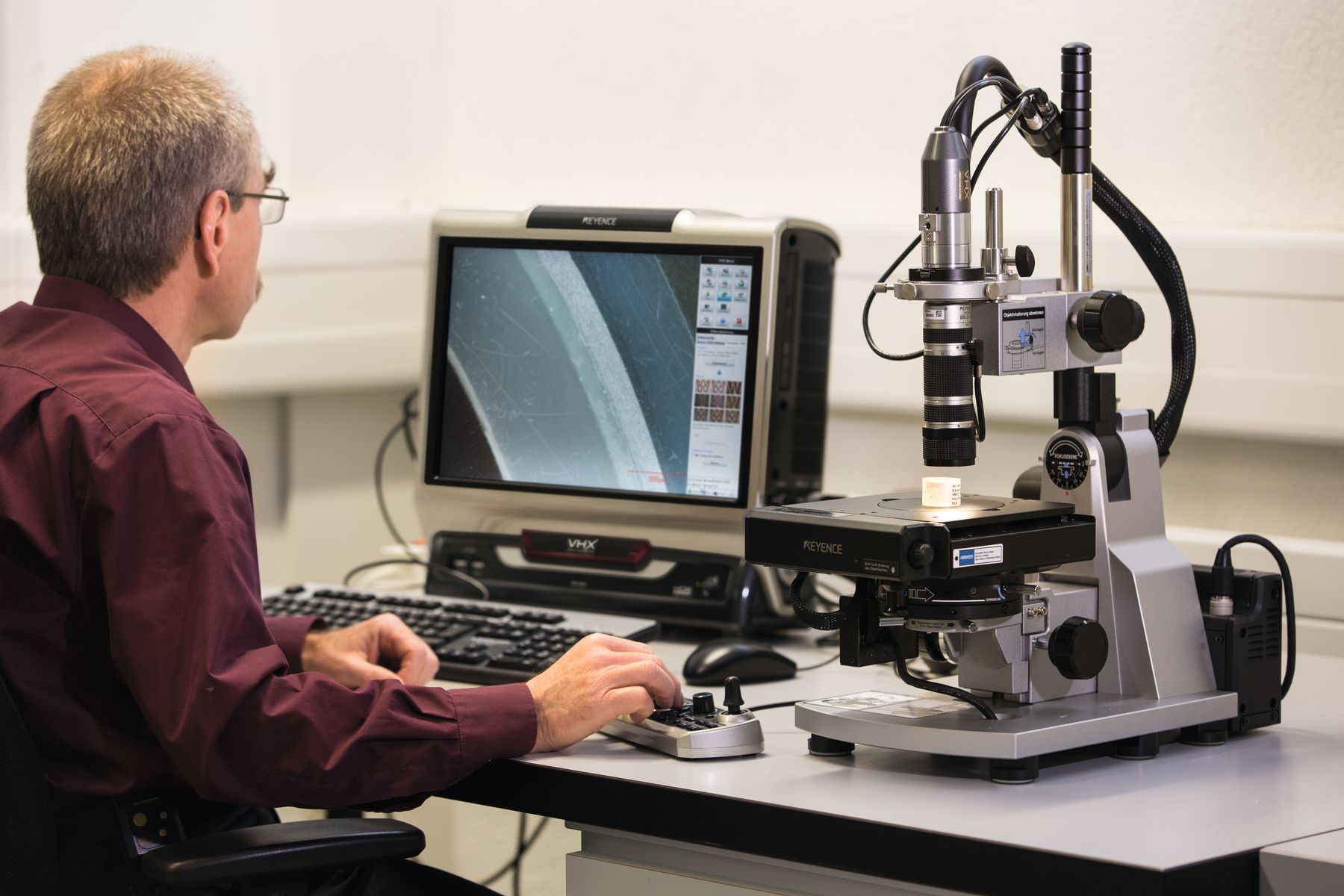

Various tests are carried out to evaluate the long-term properties of materials and predict their service life. For example, a PE material for drinking water applications is exposed for months to warm water containing a high level of chlorine in order to test how resistant it is to this relatively aggressive element. This is relevant given the fact that potable water in many places contains chlorine, albeit in very low concentrations. In another series of tests, samples of the same material are “cooked” at high pressure in autoclaves containing excess oxygen until they become brittle. The degradation mechanisms and its progression over time is then examined using state-of-the-art analytical equipment.

These tests and analyses can often take several years. If a material performs well in all of these tests, Geberit may decide to take advantage of these benefits in new or existing products.